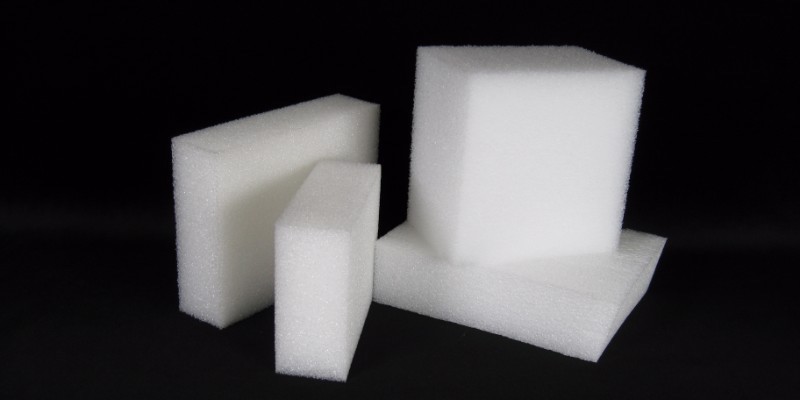

Simple Application

ET-PLANK can be easily processed into different packaging elements. They are used as technical and process packaging

Environment-friendly

ET-PLANK is 100% recyclable, environmentally friendly and non-toxic. For foaming we only use ecologically acceptable products without CFC or HCFC.

Resistance

ET-PLANK is resistant to different weather conditions while retaining mechanical performances in a wide temperature range.

Description

ET-PLANK is the monoextruded non-cross linked polyethylene foam planks produced by Isofom Srl. Thanks to its special closed-cell structure, obtained by a cpecific manufacturing process: ET-PLANK is the ideal product for all those applications requiring shock-absorbing, vibration-dampening and cushioning protection especially for heavy goods. Available in 50 and/or 100 mm thickness according to the density which varies from 220 Pcf (35kg/m3) to 900 Pcf (150 kg/m3). It can be provide, by using special additives, in black (conductive) and pink (antistatic) colors.