Environment-friendly

PlamaCELL foil is 100% recyclable, environmentally friendly and non-toxic. For foaming we only use ecologically acceptable products without CFC or HCFC.

Resistance

The PlamaCELL foil is resistant to different weather conditions, retaining mechanical performances in a wide temperature range.

Simple Application

The PlamaCELL foil is elastic and adaptable to various uses, thus reducing the amount of time required to prepare packaging and packaging waste that are adapted to the product.

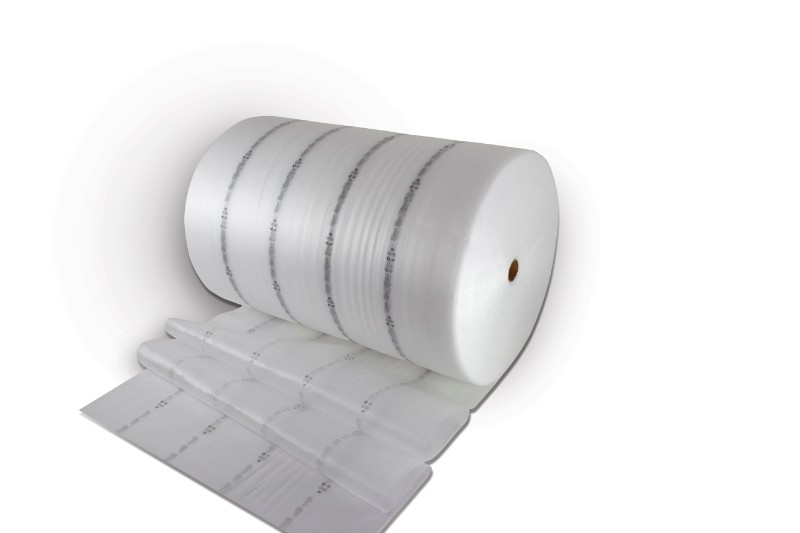

Description

PlamaCELL is a PE foam made out of closed-cell expanded polyethylene that ensures excellent protection of sensitive surfaces from scratches and mechanical injuries. The foil is light, elastic and enables simple application. Closed-cell expanded polyethylene is one of the most frequently used polymeric materials in this industry and it is made without CFC or HCFC products.